What is a Impact crusher?

Impact crushers are used as primary or secondary crushers in the process of crushing materials in mines. This type of crusher breaks and crushes minerals through the rotation of the rotor and the blows of hammers installed on the rotor.

This type of crusher is used to crush hard materials and is not applicable to crushing soft materials. The crushers produced by Roll Machine Company are divided into 3 models, and the main use of this type of crusher is in the first stage of the crushing process, in river mines, but all models can be used in the second stage of the crushing process in mountain mines.

How a Impact crusher works

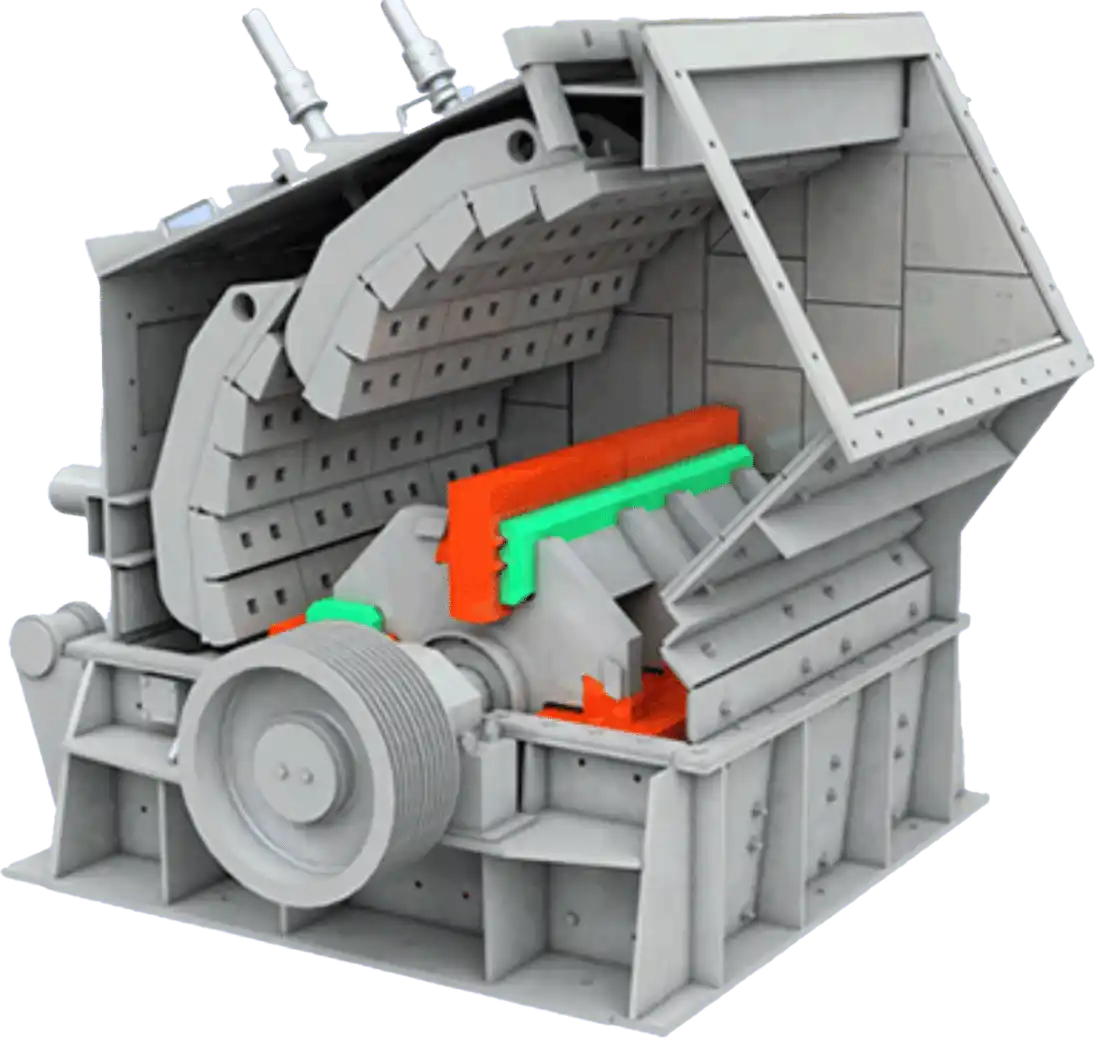

The Impact crusher is in the second stage of the crushing process, the main part of the device is the rotor, hammers and anvils. The Impact crusher has a rotor on which 4 or 8 rows of hammers are installed. Mountain or river materials in sizes of 10 to 15 cm are suitable for entering the device.

The crushing mechanism in the Impact crusher is very different from other crushers such as jaw crushers, hydrocone crushers, or VSI crushers (rock and rock). The way the Impact crusher works is that minerals enter the rock crushing area through the charge inlet. As the rotor rotates with the help of the electric motor and as a result, the hammers mounted on the rotor move, the incoming materials hit the hammers and are thrown towards the anvils installed inside the machine.

Due to the repeated blows of the hammers on the stone pieces and the collision of the stone pieces with the walls and anvils, as well as with each other, the crushing process is carried out and this process continues until the stone pieces reach the desired dimensions and exit the crusher. The Impact crusher has two or three adjustable anvils, by adjusting which the output granularity can be adjusted.

The Impact crusher hammer is a rectangular piece with a very special design and is also made of very strong and wear-resistant alloys such as manganese steel or Ni-hard, etc. Like the hammers, Impact crusher anvils are also made of very strong and wear-resistant alloys.

Technical specifications of Impact crusher

In general, the technical specifications of the Impact crusher are divided into different categories of Impact crusher parts, capacity and types of Impact crusher production models. Below we will explain the details of the issues raised.

Impact crusher parts

This device consists of the following main parts:

Types of impact crushers

Machine Roll Company offers a variety of Impact crushers in different sizes, capacities, and models from NS Impact crusher, Boehringer impact crusher, and Hazemag impact crusher:

NS Impact crusher

One of the crushers produced by Machine Roll Company is the NS series impact crusher, licensed by the Austrian Mannsberger Company. This type of Impact crusher was one of the first impact crushers produced for use in mining lines and is still in use today. The Mannsberger crusher is in the second stage of the crushing process, with the rotor, hammers, and anvils constituting the main part of the machine. The most important features of this device are its durability and easy maintenance, which can save costs and time.

One of the features of the Mannsberger impact crusher is the different design and low weight of the rotor of the device, which is very useful for crushing soft materials due to the low torque of the rotor. One of the differences of this device compared to other impact crusher is that the number of hammers in this device is 6 rows, while in other impact crusher, 4 rows of hammers are installed and between the rows of hammers, they are covered with anti-wear coatings to prevent wear.

Other differences between this impact crusher and other impact crushers are the use of steel side rails and two long anvils instead of three, as well as the smaller width of this device compared to other impact crusher for use in small mines.

Model and capacities of the Mannsberger crusher

Designing and manufacturing of the Mannsberger Impact crusher in the dimensions and capacities of the proposed models is possible according to the needs of our esteemed customers. If you wish to inquire about the price, consultation, and purchase of the Mannsberger Impact crusher, please contact the company’s experts through the contact us section.

- Impact crusher 80 (with a capacity of 80 tons per hour)

- Impact crusher 100 (with a capacity of 100 tons per hour)

- Impact crusher 120 (with a capacity of 120 tons per hour)

- Impact crusher 180 (with a capacity of 180 tons per hour)

- Impact crusher 240 (with a capacity of 240 tons per hour)

Boehringer Impact Crusher

The Boehringer Impact crusher is one of the impact crusher models that was first manufactured by the German Boehringer Company in 1940. Today, this Impact crusher is used in mining crushing lines with the same mechanism, but with more modern and powerful technologies, and is still one of the most popular types of impact crushers and is known as the Impact crusher HS series.

This type of crusher is very efficient in crushing hard materials such as iron ore due to its high power, higher production capacity and better efficiency than the Mannsberger Impact crusher and is used in most mining crushing lines. This device consists of three series of anvils, each of which operates separately and can be adjusted to control the output granulation.

The mechanism of operation of this device is that minerals enter the device from the inlet. With the help of the electric motor, the main shaft of the device is set in motion and causes the hammers mounted on the rotor to rotate at high speed. Minerals are thrown towards the anvils by hitting the hammers and are crushed by hitting the anvils and hammers as well as each other. This process continues until the minerals are adjusted to the desired size for the output.

Regular maintenance of the Behringer impact crusher at the specified time according to the device instructions can prevent unexpected events and ensure improved performance and longer useful life of the device. One of these is the removal of unnecessary particles and materials in the device.

Another thing that can be mentioned is regular and timely lubrication of parts to prevent wear and maintain the useful life of the device. Other things include periodic inspection of all parts and replacement of consumable parts such as hammers to prevent wear and maintain the useful function of the device.

Advantages of the Boehringer Impact crusher

- After-Sales Services

- High material input and output capacity

- Using robust and wear-resistant parts

- Longer life and higher productivity with periodic service

- Has three anvils with separate functions to control the output size of the materials.

- Easy and cost-effective service and maintenance by specialized technical experts

- Ability to adjust the distance between hammers and anvils for material output

- More powerful and with more up-to-date technology than the Mannsberger Impact crusher

- Maximum use of hammers due to their special design in 5 different modes

- Has a rubber guard at the opening of the device to prevent materials from being thrown out.

- Using advanced technology to reduce vibration and noise and be environmentally friendly

- Ability to crush materials with different properties and high hardness, such as iron ore

- Has a powerful rotor for crushing and reducing energy consumption due to lower inertia.

Boehringer Impact Crusher models and capacities

It is possible to design and manufacture the Boehringer impact crusher in the dimensions and capacities of the proposed models, according to the needs of our esteemed customers. If you wish to inquire about the price, consultation, and purchase of the Boehringer impact crusher, please contact the company’s experts from the contact us section.

- Impact crusher HS7 (with a capacity of 70 to 120 tons per hour)

- Impact crusher HS10 (with a capacity of 120 to 160 tons per hour)

- Impact crusher HS14 (with a capacity of 160 to 200 tons per hour)

Hazemag Impact Crusher

The Hazemag impact crusher is one of the impact models that was first manufactured by the German company Hazemag in 1946. It can be safely said that this type of impact is the most powerful impact crusher for crushing all rocks with a very high degree of hardness, and along with its very high input characteristics and at the same time its very high output production capacity compared to other impact crushers such as the Mannsberger impact crusher or the Boehringer impact crusher, it is known as one of the best impact crushers in Iran.

Today, this impact crusher is used in mining crushing lines with the same mechanism, but with more modern and powerful technologies, and is still one of the most popular types of impact crushers and is known as the Hazemag impact crusher. This device has a different rotor design and includes three series of anvils, each of which operates separately and can be adjusted to control the grain size of the output product. The different rotor design of this device is due to the installation of four rows of hammer magazines and eight hammers. Due to the different design of the hammers, they can be used to the maximum in 5 different modes.

One of the outstanding features of this type of impact crusher is the very high input capacity and very high production capacity of this device. Another feature of this device is the complete opening of the moving body of the device from both sides by the jacks installed on it, resulting in easy access to parts for repair or replacement. Another feature of this device is easy access to the lower anvil of the device. So that, considering the installation of the anvil on the rail installed in the device, the anvil moves completely back and forth, resulting in easy access to adjust the distance between the hammers and the anvil, as well as repair or replace parts completely.

The mechanism of operation of this device is that minerals enter the device from the inlet. With the help of the electric motor, the main shaft of the device is set in motion and causes the hammers mounted on the rotor to rotate at high speed. Minerals are thrown towards the anvils by hitting the hammers and are crushed by hitting the anvils and hammers as well as each other. This process continues until the minerals are adjusted to the desired size for the output.

Regular maintenance of the Hazemag impact crusher at the specified time according to the device instructions can prevent unexpected events and ensure improved performance and longer useful life of the device. One of these is the removal of unnecessary particles and materials in the device. Another thing that can be mentioned is regular and timely lubrication of parts to prevent wear and maintain the useful life of the device. Other things include periodic inspection of all parts and replacement of consumable parts such as hammers to prevent wear and maintain the useful function of the device.

Advantages of the Hazemag Impact Crusher

- After-Sales Services

- Very high material input and output capacity

- Using robust and wear-resistant parts

- Equipped with powerful jacks to open the movable body on both sides.

- Has three anvils with separate functions to control the output size of the materials.

- Easy and cost-effective service and maintenance by specialized technical experts

- Ability to grind materials with different properties and very high hardness

- More powerful and with more up-to-date technology than other Impact crushers

- Maximum use of hammers due to their special design in 5 different modes

- Has a rubber guard at the opening of the device to prevent materials from being thrown out.

- Using advanced technology to reduce vibration and noise and be environmentally friendly

- Has a powerful rotor for crushing and reducing energy consumption due to lower inertia.

Model and capacity of the Hazemag Impact crusher

Designing and manufacturing the Hazemag impact crusher in the dimensions and capacity of the proposed model is possible according to the needs of our valued customers. If you would like to know the price, advice, and purchase the Hazmag impact crusher, please contact the company’s experts through our contact us section.

- Hazemag impact crusher (with a capacity of 200 to 250 tons per hour)

Impact crusher price

Considering the important factors discussed in the sections described, such as dimensions, capacity, weight, etc., one of the most important factors in choosing a impact crusher is the price factor. As we have already mentioned, ordering a device with larger dimensions will also increase the price. It should be noted that due to fluctuations in the price of the dollar and steel products, which are the basis of the raw materials for the construction of impact crushers, it is not possible to determine a fixed and specific price for this device. For information on prices, advice, and ordering a Impact crusher, please contact the company’s experts through our contact us section.