The Jaw Crusher is one of the primary crushing machines used in mines. It is primarily utilized for processing mineral materials and different aggregates at the initial stages of crushing. This device is designed and built for crushing larger materials exceeding 20 cm in size and is widely used in various industries for mineral processing and aggregate production. Below, we provide more details about its specifications, mechanism, features, purchasin

In general, the process of size reduction is called crushing or so-called grinding. In general, the crushing process is carried out in several stages, depending on the size and type of minerals, and is divided into two categories: primary crushing and secondary crushing. Jaw crushers are widely used in primary crushing processes and are also called primary crushers.

What is a jaw crusher?

One of the types of crushers used in crushing lines is the jaw crusher model. This type of crusher is located in the initial crushing lines of mines and is responsible for the crushing process of coarse rocks and processing minerals. Due to the reduction of depreciation and increase in the life of parts during continuous crushing operations in mines, all parts used in the machines are made of anti-corrosion and high-quality manganese steel.

The Jaw Crusher of Machine Roll Company is designed and manufactured as the primary crusher in crushing lines, with a thick, sturdy body and precise and technical welding, for processing various minerals and materials with dimensions of more than 20 centimeters, and is used in mines.

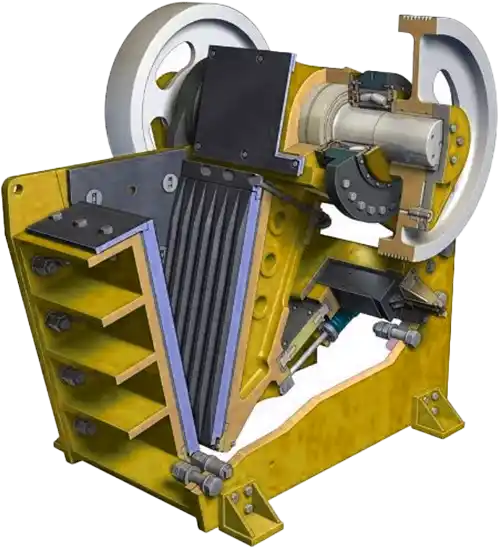

The crushing process in a jaw crusher is carried out by the pressure force between the two jaws. The jaws of this device are placed on two fixed and movable plates, and in order to prevent the erosion of the jaws due to constant contact with minerals and to provide the desired resistance, the jaws of this type of crusher are made of manganese steel and are made in a wavy shape.

How a jaw crusher works

Materials enter the crushing chamber (the space between the fixed and moving jaws) through the input opening. Using the force generated by the electric motor, the motion of the shaft and toggle crushes the material. The crushed material exits through the lower gap between the two jaws, known as the discharge gap, and can then proceed to secondary crushing lines.

Jaw crusher specifications

In general, the technical specifications of the jaw crusher are divided into different categories of jaw crusher components, dimensions and capacities of jaw crusher production models. Below we will explain the details of the issues raised.

Jaw crusher components

This device consists of the following main parts:

- Crusher Body

- Flywheel

- Toggle

- Fix Jaw

- Movable Jaw

- Eccentric shaft

- Bearing

- Bearing

- Bearing

- Tension rods and springs

- Outlet Throttle Adjustment Jack

- Electromotor

- Belt pulley

Specifications and Models

Things to consider when ordering this product are the dimensions of the device, the weight of the device, and the output capacity required in the crushing lines. It can be noted that by increasing the dimensions of the jaw crusher, the operating capacity of the device increases and it also brings more profitability to the esteemed customers. However, naturally, due to the increase in the amount of material and steel used in the device, its price will also be directly affected.

It should be noted that the design and construction of jaw crushers in dimensions and capacities higher than the models presented is possible, according to the needs of our esteemed customers. If you wish to inquire about the price, consultation, and purchase of a jaw crusher, please contact the company’s experts from the contact us section.

The general principles of naming the models of this device are determined based on the size and model of the crusher according to the dimensions of its opening. For example, the model crusher (90*110) represents a jaw crusher with a stone inlet opening measuring 110 x 90 centimeters.

- Model 110 x 90

- Model 100 x 120

- Model 100 x 80

- Model 100 x 63

- Model 90 x 60

- Model 90 x 40

- Model 90 x 30

- Model 80 x 55

- Model 75 x 45

Advantages of jaw crusher

Jaw crusher is the best type of stone crusher that is used at the beginning of the mining crushing lines. The most important advantage of this type of stone crusher over other crushers is its high power and simple structure, with the function of reducing the dimensions of large and very hard and erosive stones. Other advantages of this product are as follows:

- After-Sales Services

- Stable and consistent performance

- High capacity in material production

- Very easy and simple lubrication system

- Ability to adjust the throttle according to the material output

- Longer life and higher productivity with periodic service

- High and strong power in crushing hard materials

- Providing all spare parts as soon as possible and at the lowest cost

- Very low depreciation of the device by using parts made of anti-wear alloy

- Easy and cost-effective service and maintenance by expert technicians

- Thick and sturdy body made of manganese steel and precise and technical welding

- Greater efficiency by loading the machine with minerals of appropriate dimensions and weight.

Outstanding features of jaw crusher

- Very high capacity in crushing minerals

- Easy and cost-effective service and maintenance

- All parts used in the machine are made of the best anti-wear alloys.

- Has a thick, sturdy, and wear-resistant body made of manganese steel

- Equipped with an outlet throat adjustment jack to exploit minerals in the dimensions required by the crushing lines.

- High power and stable performance in crushing various types of coarse and very hard minerals in mining lines

Jaw crusher price

Considering the important factors discussed in the sections described, such as dimensions, capacity, weight, etc., one of the most important factors in choosing a jaw crusher is the price factor. As we have already mentioned, ordering a machine with larger dimensions will also increase the price. It should be noted that due to fluctuations in the price of the dollar and steel products, which are the basis of the raw materials for making a jaw crusher, it is not possible to determine a fixed and specific price for this machine. For information on prices, advice, and ordering jaw crushers, please contact the company’s experts through our contact section.