What is Hydrocone?

In mining crushing lines, to produce the materials needed in concrete and asphalt projects by crushing minerals, it is necessary to use different machines in terms of mineral dimensions, input capacity, material production capacity, etc. One of the machines used to produce sand is Cone Crusher The hydrocone crusher is known by other names such as cone crusher, cone sand maker, hydrocone, and in English, cone crusher. (Cone Crusher) نیز شناخته می شود.

Due to its conical design, this type of crusher is also known as a cone crusher. Hydrocone is used to crush very hard minerals such as iron ore. In the process of mining crushing lines, coarse mineral rocks are separated from the heart of the mountain by the primary crusher such as The jaw crusher crushes rocks into smaller pieces.

The crushed stones are then sent via conveyor belt to Impact crushers to be reduced to a standard size such as the Boehringer impact crusher or the Hazmag impact crusher Finally, the crushed minerals, after going through the above crushing stages, are transferred to Hydrocone or VSI crushers are transported to produce sand.

Cone crusher or cone sand makerDue to its pressure crushing function, unlike impact crushers, it flakes the rocks and turns them into very fine grains called sand. The important point in this type of crusher is that by adjusting the pressure of the oil pump, the output can be produced according to the wishes of the esteemed customers. It can be noted that the alloy of the main parts of the hydrocon is made of molybdenum steel, which has a very high resistance to wear and tear, and all parts are automatically lubricated and lubricated.

How a Cone crusher works

One of the secondary crushing devices in mining production lines is the Cone crusher machine roll. This crusher is of great interest to mines operating in this field due to its very high input capacity and very high output production capacity, as well as the crushing of very hard minerals such as iron ore, etc. The cone crusher crushes very large stones obtained from mines into flakes under pressure and converts them into much smaller pieces called sand.

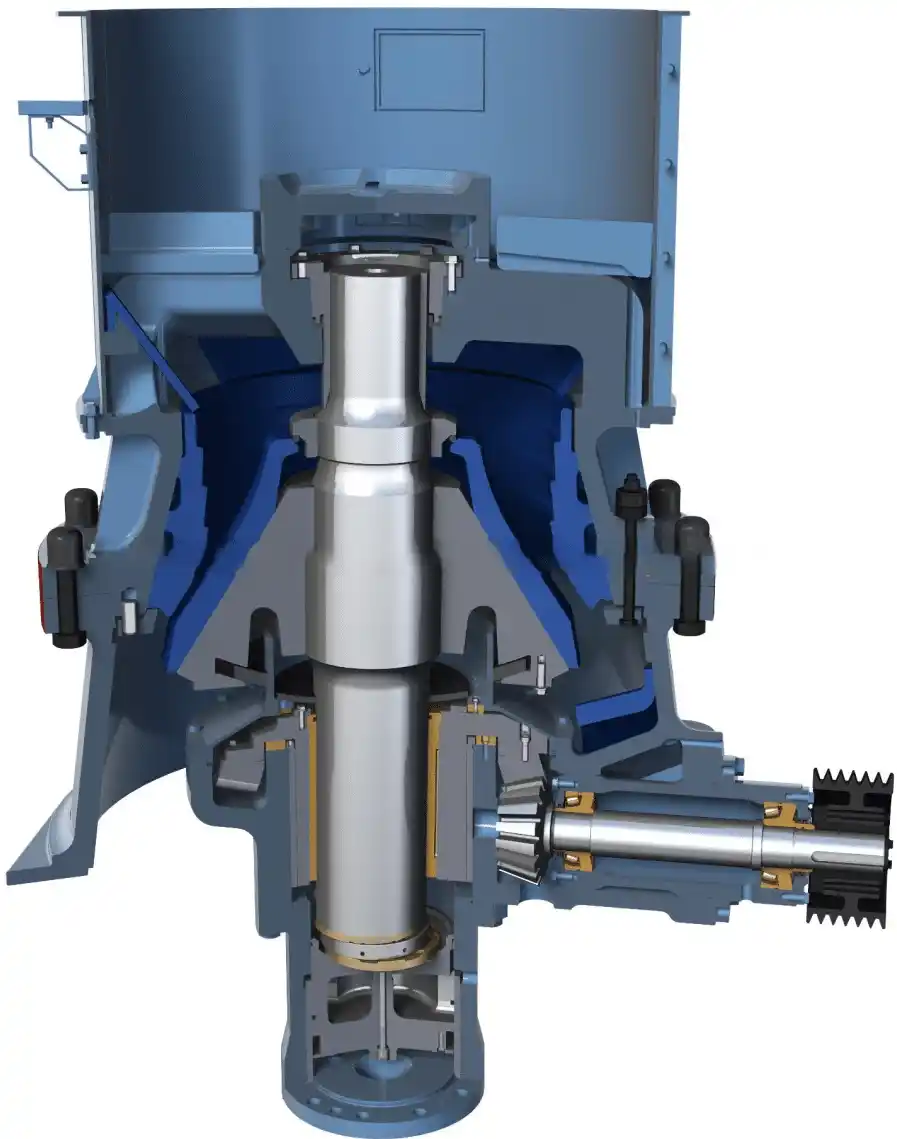

The crushing process in the hydrocone is carried out by the pressure between the two important parts of the device, called the mantle and the concavity, and the movement of the main shaft crank. The concavity part is fixed and the mantle is located in a conical shape inside the concavity. All the parts mentioned are installed inside the top shell and bottom shell. An important point in the conical sand making machine is the ability to adjust the distance between the mantle and the concavity. This distance can be adjusted with the help of oil and a hydraulic pump from the bottom of the machine.

If more oil is injected into the bottom of the machine by the hydraulic pump, it moves the main shaft upwards, and as a result, the distance between the mantle and the concave decreases, and the minerals are crushed into smaller pieces. On the other hand, if less oil is pumped into the machine, the distance between the mantle and the concave increases, and as a result, the output of the minerals will be larger pieces.

The movement of the main shaft is such that the pinion gear is moved by the force of the electric motor and transfers its rotational force to the crank gear. As a result of the movement of the crank gear, the eccentric crank bushing moves the main shaft in a cranked manner. The cranked movement of the main shaft also moves the mantle in a cranked manner, and as a result, due to the cranking of the mantle and the approaching of the mantle to the concave, the minerals are put under pressure and cause them to be crushed.

For optimal use and production of quality materials, the size of the cone crusher or hydrocone can be changed., changed the speed of the rocks’ exit so that very strong and solid rocks are broken at a low speed and the crushing and sand-making operations are carried out well. By reducing the distance between the mantle and the concave, flake-shaped particles can be achieved.

Technical specifications of the hydrocone

In general, the technical specifications of the cone crusher are divided into different categories of cone crusher components, types of hydrocone, dimensions and capacity of hydrocone crusher production models. Below we will explain the details of the issues raised.

Cone crusher components

The cone crusher consists of the following main parts:

Types of hydrocones

Machine Roll Company offers various types of Hydrocone crushers in different sizes, capacities and models of fine crushers, medium crushers and coarse crushers (superior or gyratory):

- Hydrocone crusher 36 * 2

- Hydrocone crusher 36 * 3

- Hydrocone crusher 36 * 4

- Hydrocone crusher 36 * 5/5

- Hydrocone crusher 36 * 7

- Hydrocone crusher 36 * 9

- Hydrocone crusher 36 * 11

- Hydrocone crusher 36 * 13

Dimensions and capacity of hydrocone crusher production models

Things to consider when ordering different models of this product are the input and output capacity, and the placement of the device as a primary crusher or secondary crusher in the crushing lines. It can be noted that by increasing the dimensions of the device like Superior, the operating capacity of the device increases and it also brings more profitability for the esteemed customers. However, naturally, due to the increase in the amount of material and steel used in the device, its price will also be directly affected.

A very important point regarding the input and output load in this device is the size of the mantle and the concave. By changing the size of the two mentioned parts, the input and output of materials can be controlled in terms of dimensions. One of the differences between the fine crusher and the coarse crusher in this device is the dimensions and capacity of the mantle and concave and the top shell piece installed in the device.

The naming principles of this type of crusher models are determined based on the wide opening of the mantle, which is equivalent to 36 inches or about 915 millimeters, and this device is known as the 36-inch hydrocone. Depending on the placement of the device in the crushing lines, whether it is used as a primary crusher or coarse crusher at the beginning of the line or as a secondary crusher or fine crusher at the end of the line, the size of the top shell varies and a larger top shell is needed for larger material input.

It should be noted that the design and construction of this type of crusher in the dimensions and capacities of the proposed models is possible according to the needs of our esteemed customers. If you wish to inquire about the price, consultation, and purchase of a hydrocon crusher, please contact the company’s experts from the contact us section.

Advantages of cone crusher

- After-Sales Services

- Automatic protection system

- High material input and output capacity

- Using robust and wear-resistant parts

- Automatic lubrication and greasing of all parts

- Longer life and higher productivity with periodic service

- Ability to adjust the distance between the mantel and concave for the direction of material output

- Placement as primary and secondary crusher in crushing lines

- Easy and cost-effective service and maintenance by specialized technical experts

Cone crusher price

Considering the important factors discussed in the sections described, such as dimensions, capacity, weight, etc., one of the most important factors in choosing a cone crusher is the price factor. As we have already mentioned, ordering a machine with larger dimensions will also increase the price. It should be noted that due to fluctuations in the price of the dollar and steel products, which are the basis of the raw materials for making cone crushers, it is not possible to determine a fixed and specific price for this machine. For information on prices, advice, and ordering cone crushers, please contact the company’s experts through our contact us section.